ONE-STOP SOLUTION PROVIDEER FOR THE FOOD INDUSTRY

High-Quality Craft Peach Pineapple Canned Fruit Production Line Solution

◉ Customized Power and Output

◉ Suitable for All Fruit Processing

◉ Simple Operation and Quick Production

◉ High Degree of Automation

Product advantages

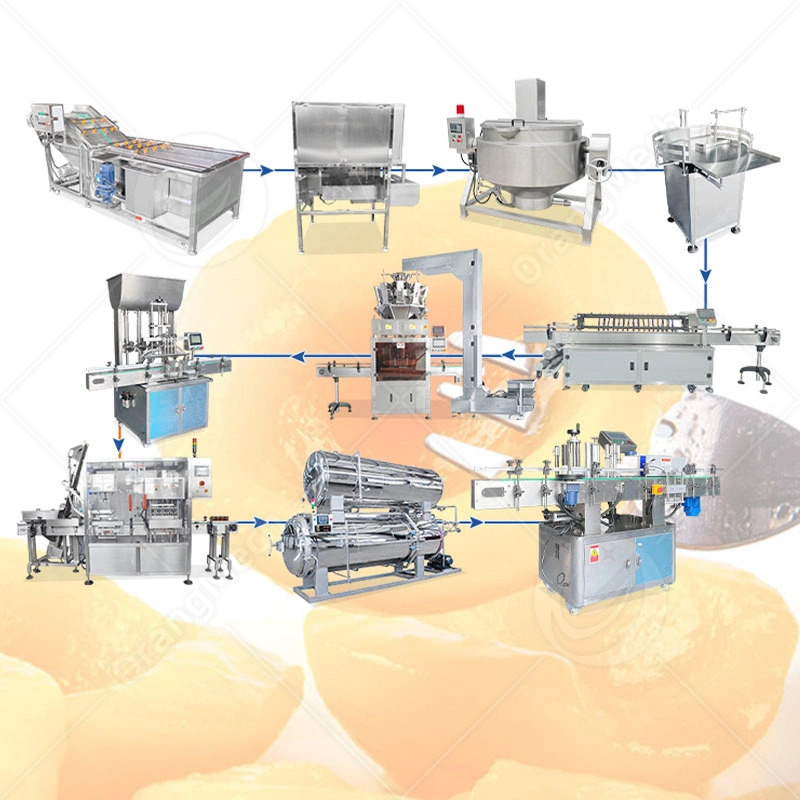

01

Bubble vegetable and fruit wash machine

Remove dirt, impurities and fluff on the surface of the material to ensure the cleanliness of the material.

02

Peeling and core removal machine

Remove the skin and core of the material to obtain the pulp part that can be used to make canned food.

03

Jacketed cooking pot

Put the cut pulp into the pot, add appropriate amount of water and other auxiliary ingredients to heat and cook.

04

Reverse bottle washing machine

Glass bottles are transported to the bottle washing machine through a conveyor belt, where they are washed and drained.

05

Multi-head weighing filling machine

Filling according to the set weight or volume to ensure that the pulp content in each can is uniform.

06

Liquid filling machine

The bottles filled with pulp are added with the prepared liquid through a conveyor belt.

07

Vacuum capping machine

Extract air from the filled cans and seal them with caps.

08

High temperature autoclave

Using high temperature and steam to make canned food healthier and extend its shelf life.

09

Labeling machine

This machine accurately sticks pre-designed labels on the surface of cans.

Production process

Product application

◉ Canned fruit factory: It specializes in producing different kinds of canned fruits, such as classic and common canned peaches, pineapples and mangoes.

◉ Catering and baking shops, etc.: It is very suitable for food processing plants to provide canned fruits for catering and other industries, and can also be used for desserts in baking shops.

◉ Beverage industry: Drinks such as fruit granules and yogurt that need to be added in beverages can be realized by fruit processing equipment.

Contact Person:Karen

Tel: +86 13323958325

ADD:

No. 1016, Dahe Garden, Taihangshan Road, Yancheng District, Luohe City, Henan Province